printing

Mastering DTF Printing: A Step-by-Step Guide for Blank Shirt Brilliance

In the vibrant realm of garment decoration, the resurgence of direct-to-film (DTF) printing has elevated the possibilities, ushering in a renaissance in the way we bring designs to life on blank shirts. At the heart of this transformation lies the synergy between DTF technology and the precision of a heat press.

This guide unravels the intricacies of DTF printing, with a specific focus on leveraging DTF stickers to create stunning visuals on blank shirts.

Understanding DTF Printing

Decoding Direct to Film (DTF) Technology: As we embark on this journey, it’s crucial to understand the core principles of DTF printing. Distinguishing itself from sublimation, DTF involves the meticulous application of ink directly onto a film, creating vibrant and durable designs. At the forefront of DTF mastery are the ingenious DTF stickers, which encapsulate the design with precision and clarity.

The Intricacies of DTF Stickers: DTF stickers, the unsung heroes of this process, play a pivotal role in achieving intricate designs. These stickers, crafted with precision, act as carriers of vibrant ink, ensuring that every nuance of the digital artwork is faithfully transferred onto the blank shirt. The layering capabilities of DTF stickers unlock a realm of possibilities for multi-colored and detailed designs.

Essential Materials and Equipment

Blank Shirts: The Canvas for DTF Mastery: The foundation of any DTF masterpiece is the blank shirt itself. The choice of fabric and color sets the stage for the artwork to shine. From cotton to polyester blends, the blank shirt becomes the canvas where creativity meets wearability.

DTF Inks: Vibrancy and Durability Unleashed: Central to the DTF process is the ink that brings designs to life. DTF inks, known for their vibrancy and durability, adhere seamlessly to the fabric, creating prints that withstand the test of time and multiple washes. These inks, available in a spectrum of colors, open up a palette for limitless creativity.

Source: brildor

Heat Press Machines: Precision in Application: The heat press machine becomes the artisan’s tool in this process, ensuring that the DTF stickers are meticulously adhered to the blank shirt. Precision temperature control and even pressure distribution are the hallmarks of a quality heat press, contributing to the longevity and brilliance of the final print.

Preparing Your Artwork for DTF

Digital Design Mastery: Before the magic happens, digital design mastery sets the tone. Calibrating color profiles, ensuring vibrancy, and optimizing images for DTF perfection become crucial steps. The digital design becomes the blueprint for the masterpiece that will soon grace the blank shirt.

Printing DTF Stickers

Loading the DTF Film into the Printer: The first dance in the DTF ballet involves loading the DTF film into the printer. This delicate process ensures that every layer of the design is accurately reproduced. The film, akin to a conductor’s sheet music, carries the intricate details that will soon come to life.

The Precision of the DTF Printing Process: As the printer engages in the rhythmic dance of depositing ink onto the DTF film, precision is key. Layer by layer, the DTF stickers take shape, capturing the nuances of the digital design. The role of white ink becomes particularly crucial, ensuring that colors pop and details shine.

Curing DTF Prints with a Heat Press

Setting the Stage: Preparing the Heat Press: As the printed DTF film takes its final form, it’s time to set the stage for curing. Preparing the heat press involves ensuring that the temperature is calibrated for optimal curing without compromising the integrity of the fabric or the ink.

The Ballet of Temperature and Pressure: The delicate ballet of temperature and pressure unfolds as the heat press engages with the DTF stickers on the blank shirt. Achieving optimal heat distribution ensures that the ink bonds seamlessly with the fabric, creating a durable and vibrant print that withstands the test of wear and time.

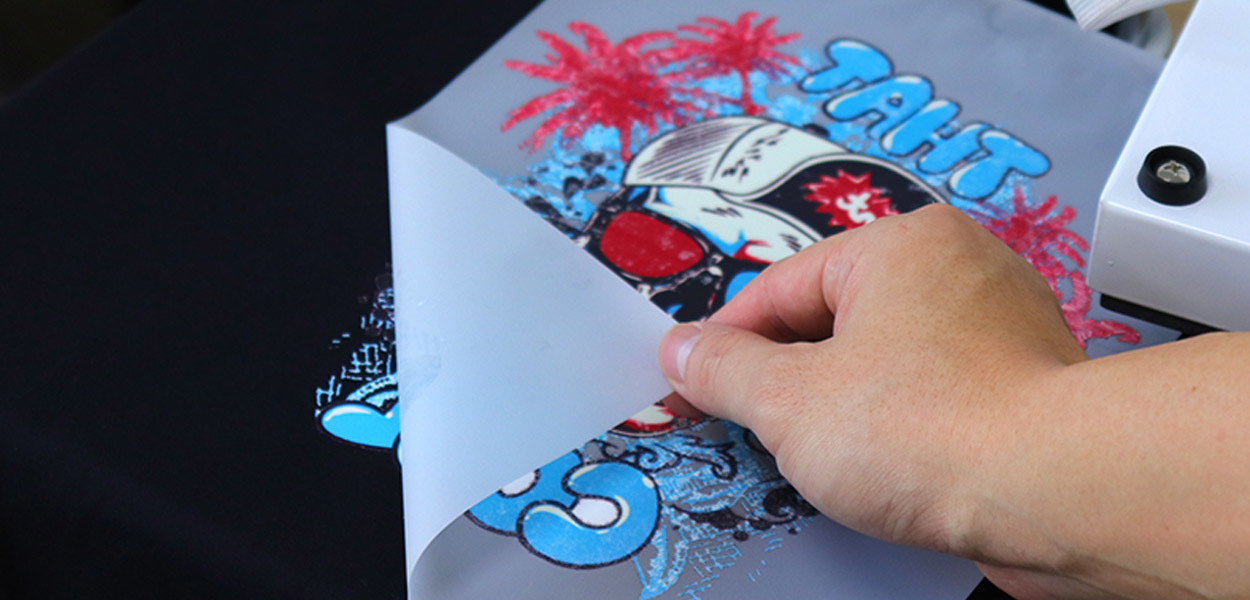

Peeling and Post-Processing

The Unveiling: Peeling Away the Film: With the heat press having performed its final act, the unveiling begins. Peeling away the DTF film reveals the masterpiece beneath. This moment is akin to an art reveal, where the digital design transforms into a tangible, wearable work of art.

Source: hanrunpaper

Post-Curing Considerations: The post-curing phase involves inspecting the print for quality assurance. Every detail is scrutinized to ensure that the colors are vivid, the lines are crisp, and the overall presentation meets the standards of the artist. The final touch involves pressing the cured print, ensuring that it sits seamlessly on the fabric.

Troubleshooting Tips and Advanced Techniques

Troubleshooting Common DTF Challenges: As with any artistic endeavor, challenges may arise. Troubleshooting common DTF challenges, such as ink saturation issues or perfecting registration for multi-layer designs, becomes part of the learning process. Mastery in troubleshooting refines the art of DTF printing.

Pushing the Boundaries: Advanced DTF Techniques: For those seeking to elevate their craft, pushing the boundaries with advanced DTF techniques becomes the next frontier. Experimenting with textures, and finishes, and incorporating DTF into artistic apparel masterpieces propels the artist into a realm of limitless creativity.

In the tapestry of garment decoration, the art of DTF printing on blank shirts with a heat press emerges as a symphony of technology and craftsmanship. From the choice of DTF stickers to the precision of the heat press, each step contributes to the creation of wearable art.

As artists delve into this realm, they unlock a canvas where creativity knows no bounds, and DTF becomes not just a process but a transformative journey in garment decoration.